One of the things I had hoped to bring to the company I bought was innovation. That word gets thrown around a lot, and can mean different things to different folks. To me, it means applying new ways to get work done more efficiently.

While immediately I could see things that could be improved in efficiency, I was following the formula of trying to change very little for the first 3 months. During this time, I asked many questions, such as, why do we do it this way, is this the best way of doing this, is there another way to do this, etc? These questions were mostly met with that’s how we have always done it, or we tried other methods and this is the best way.

For one of the products we make in quantity, we cut up a product call coco mat. It is coconut shell shreds that are glued together. While measuring the time and money it took to make this product, I realized that not only was the process of cutting and trimming the coco mat inefficient, it was somewhat dangerous.

To process these sheets of coco mat into the plugs of coco mat we needed, the guys would draw the circles on a sheet. Then the bandsaw blade would be turned around so that it was running backwards. Then a considerable amount of force was used to cut these circles out. This would get them in a shape from somewhat circular to square. Then each one would be hand trimmed with large sheers that needed constant sharpening to make the correct profile.

I challenged the guys to think of another way, while I investigated several methods myself, and could not find a tool made that would do what I wanted. One of the guys decided to make a tool. It was essentially a large sharpened pipe. This tool was tested in a hydraulic press, and worked beautifully. It required 800 lbs of force to cut through the coco mat. While this worked, it was still really slow and required pre-cutting the coco mat to fit into the hydraulic press.

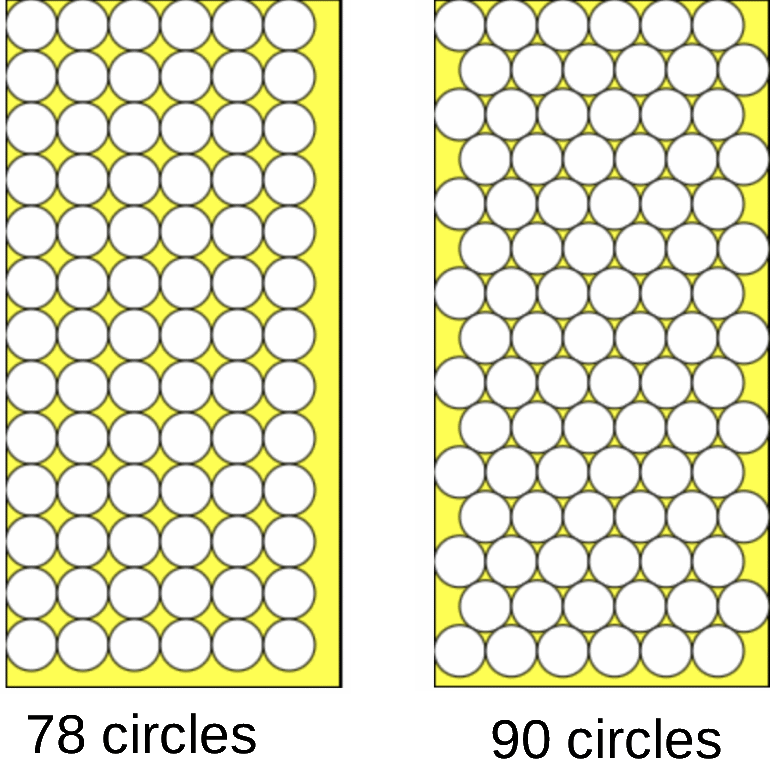

While discussing a better solution, we talked about using more leverage, thus getting fingers away from the cutting action. This led to the realization that we had an arbor press that had a four-foot handle. The guys further modified the tool to allow it to clamp to the arbor press. This enabled cutting of the coco mat without pre-cutting, pre-marking, etc. Further, because this method allowed for safely cutting really close to the other circles, it allows us to cut more circles out of each sheet.

https://www.engineeringtoolbox.com/circles-within-rectangle-d_1905.html

This innovation took processing time from over 10 minutes per coco mat plug to less than 30 seconds. Since we make hundreds of these a year, it was a huge win. This win not only saves us time, thus making more money, but also makes the operation safer. Additionally, it helped me gain respect with my team, not for solving this problem, but for empowering them to solve it.

Will you give any bonuses for this innovation?